Fashions True Climate Solutions

Re-Evaluating the Methane Report

A new white paper, “A First Methane Footprint for the Fashion Industry”, argues that leather, wool, and cashmere together drive roughly 75% of fashion’s methane footprint and estimates total industry methane at ~8.3 Mt CH₄ per year. That spotlight on methane is useful—and overdue. But jumping straight to “move away from animal materials” misses where the biggest, fastest wins actually are for climate.

The goal here isn’t to wave away methane; it’s to zoom out and prioritize the highest-leverage actions—the ones that bend the curve fastest and furthest.

Put both frames on the table: methane and total GHG

Understanding the full climate picture requires a dual lens:

Methane, by human source (global, best-available science)

Agriculture (mainly enteric fermentation): ~40%

Fossil fuels (oil & gas + coal, leaks/venting): ~35%

Waste (landfills, wastewater): ~20%

These are the dominant anthropogenic methane sources; cutting them is the fastest way to cool the near term. GIJN

Full greenhouse gases, by sector (all gases, not only CH₄)

Energy (electricity, heat, fuels, transport, industry energy): ~73%

AFOLU (agriculture, forestry & land use): ~18–20%

Waste: ~3–4%

Energy overwhelmingly dominates global GHGs. That context matters for any fashion climate plan. Our World in Data

Why this dual lens matters

Methane drives near-term warming (≈86× CO₂ over 20 years; ≈27× over 100), so fast methane cuts buy time. But the energy system still drives most total warming—so decarbonizing energy is the primary lever for absolute emissions. We need both.

Energy overwhelmingly dominates global GHGs. That context matters for any fashion climate plan. Our World in Data

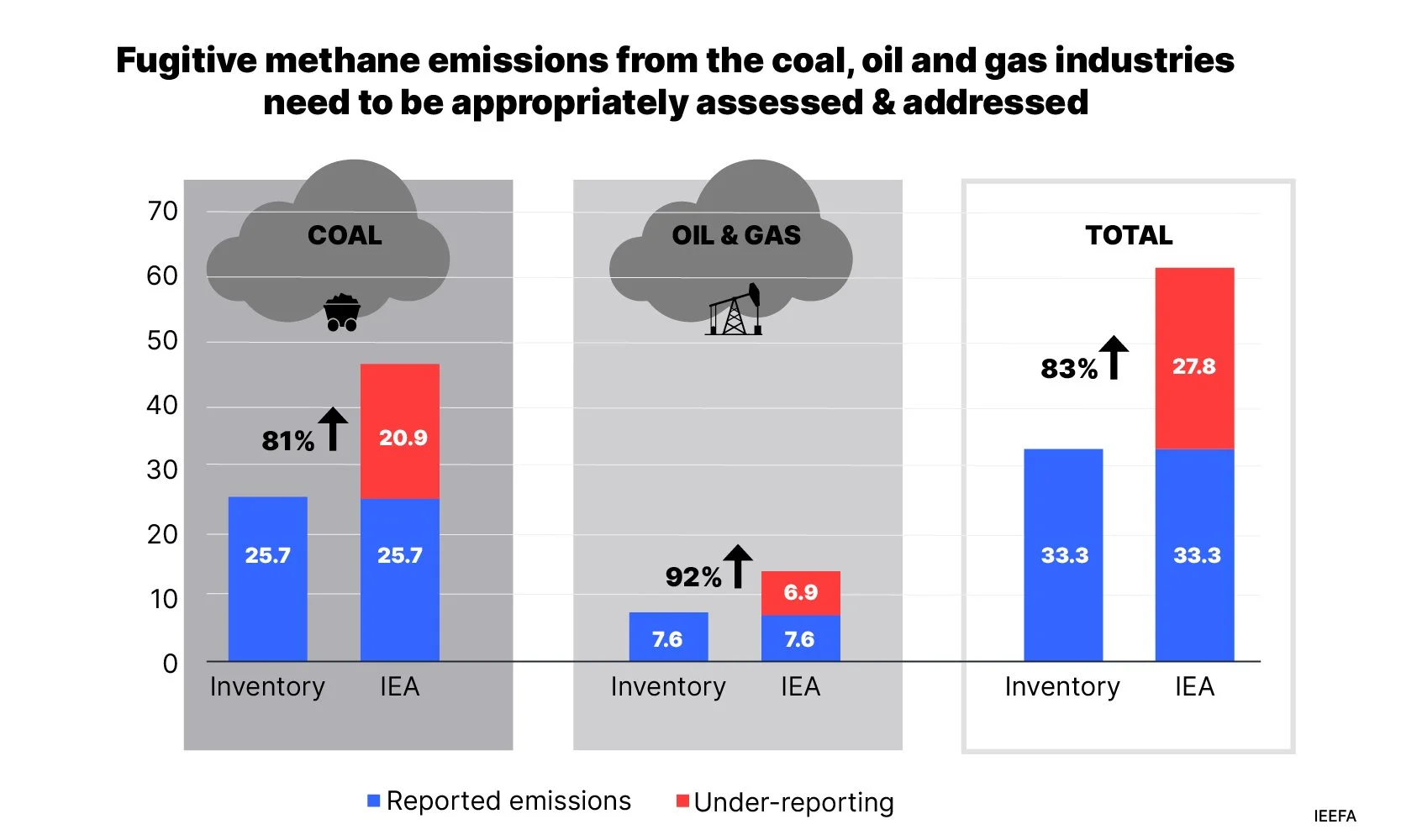

Institute for Energy Economics and Financial Analysis.

Where the quickest methane wins live: the energy system

The IEA finds ∼70% of fossil-fuel methane could be avoided today with existing tech, and roughly one-third could have been cut at no net cost in 2024 because captured gas can be sold.

Crucially, global analysis shows that fugitive methane emissions from the oil and gas supply chain have been grossly underestimated in official inventories, with one study indicating under-reporting by as much as 90% in the sector. This failure to address readily available fixes—the fugitive emissions from drilling, transport, and processing—is an economic and environmental failure driving immediate warming. This is the lowest-hanging fruit on Earth—and it’s still largely unpicked.

Abandonment is Not the Answer: Regenerative Farming is

The CFJ report’s core recommendation—rapidly moving away from leather, wool, and cashmere—treats materials in isolation from system dynamics.

The Cattle Problem: Co-product Accounting Matters

The majority of animal-related fashion methane is attributed to leather (54.1%), but the primary source is cattle raised for beef. This raises the critical co-product vs. byproduct debate.

The report in question uses a co-product calculation, inflating leather’s footprint. This is despite the fact that LCAs typically assign only 5–10% of total cattle system emissions to hides. In reality, if the world stopped buying leather tomorrow, the cattle would still be raised for beef, hides would become a massive waste stream, and the only real outcome would be higher beef prices.

Abandonment doesn’t solve the methane problem—addressing beef production practices does. The fastest and most direct lever for methane reduction in cattle is feed additives, not system abandonment:

3-NOP (Bovaer®), already approved in multiple markets, can reduce enteric methane emissions by 30–80%, depending on the production system.

Seaweed (Asparagopsis) supplements show reductions of up to 80%, though scaling is still a challenge.

These technologies work immediately and at scale, far faster than waiting for systemic shifts in grazing models.

The bottom line: We should not abandon a material that will exist as long as beef is produced. Instead, we must demand better practices — such as rapid adoption of methane-reducing feed additives — to decarbonize existing systems. The fastest path forward is reform, not refusal.

Wool & Cashmere: A Methane Sink Strategy

Wool and cashmere together contribute about 21.1% of the fashion industry’s methane footprint. Calls to move away from these fibers are short-sighted when the sector is already advancing meaningful solutions through Regenerative Agriculture.

Better grazing and land stewardship can increase soil organic carbon and restore ecosystem function. This can partially offset herd emissions on suitable landscapes. While the magnitude and durability of soil carbon gains vary and remain debated, regenerative agriculture must be pursued for its multiple co-benefits (soil health, water retention, biodiversity) while being transparent about the carbon math. India Environment Portal

The Path to Zero: Regenerative vs. Conventional LCA

When regenerative practices are applied, the greenhouse gas profile of wool can flip from net emitter to potential climate solution:

Material & System

Wool Sweater (Conventional)

Regenerative Wool Sweater

Polyester Sweater

Total CO₂e (Garment Estimate)

≈27–40 kg CO₂e

≈5–20 kg CO₂e (possible net-negative)

≈8–15 kg CO₂e *see flawed calculations

Main Climate Drivers

Enteric methane

Soil carbon sequestration offsets

Fossil fuel extraction & processing

With regenerative management, these fibers can shift from a liability to becoming climate-smart natural fibers—delivering ecological benefits while competing directly with synthetics on emissions.

The Cost of Synthetics is Flawed

The report's low methane figure for synthetics is misleadingly low because it fails to capture the full climate liability of the fossil fuel supply chain:

Misleading Methane: The low figure only reflects a partial cost assigned to the electricity used in the factory. It fails to assign the massive, uncounted fugitive emissions from the global petroleum supply chain that creates the raw plastic material itself. IEA/UNEP

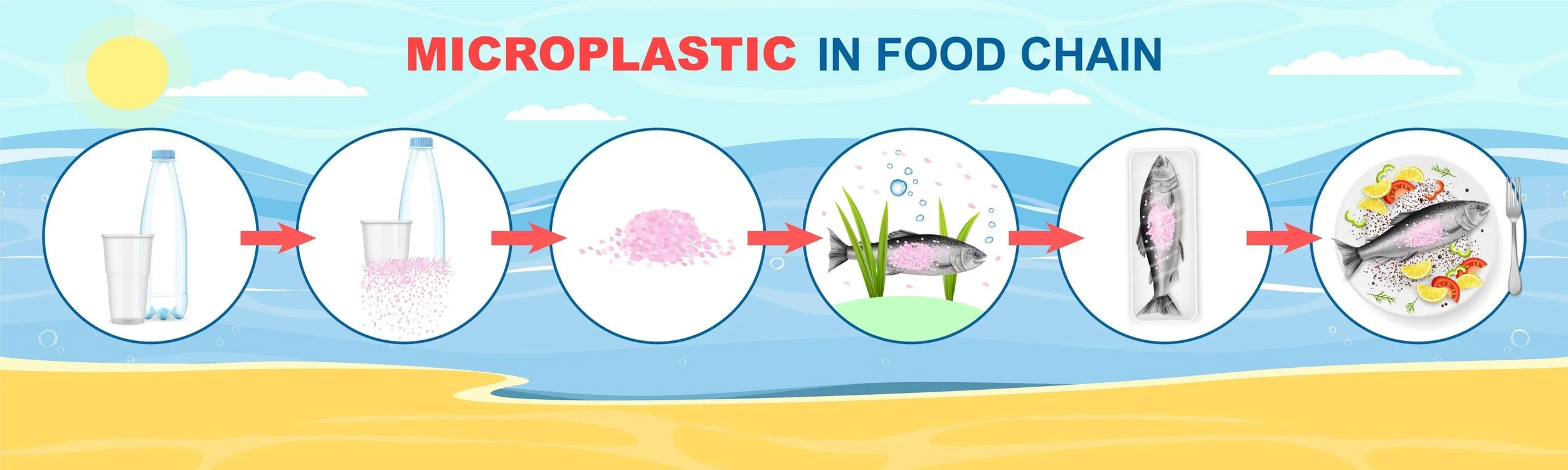

Permanent Pollution and Lock-in: The use of synthetics not only locks us into actively financing the fossil fuel sector but also contributes to microplastic contamination. Every wash releases microfibers that are now ubiquitous, detected in human blood, hearts, and reproductive organs.

Fashion's 55% Energy Crisis is the Real GHG Problem

The single most potent area for fashion to reduce its global footprint is not materials, but energy.

The vast majority of fashion's climate problem sits in its processing supply chain, known as Tier 2 manufacturing (dyeing, finishing, tanning, and thermal processes). Recent industry roadmaps peg this stage alone at ≈50%−55% of the industry's total GHG emissions—the single largest bucket to decarbonize. Cascale

This 55% Crisis exists because these facilities, often located in Asia, rely heavily on fossil fuels (coal and gas) for the high heat and steam necessary for processes like dyeing.

Expanding the Fix: Addressing the Other ∼35%

While Tier 2 factories are the core focus, brands must also address emissions across the rest of the supply chain (∼35% of the GHG footprint, including raw materials, transport, retail, and end-of-life). Transportation and logistics, in particular, offer a significant opportunity for reduction: brands should actively push suppliers toward adopting electric vehicles and clean logistics methods for last-mile delivery, scaling down the reliance on traditional fossil fuels.

Actionable Steps for Brands: A Holistic Strategy

To achieve the greatest impact, brands must pivot their investments toward the high-impact levers of energy reform and regenerative practices:

1. Mandate Renewables (The 55% Fix)

Commit to 100% Clean Energy: Immediately mandate a transition to solar, wind, or certified green grids for all manufacturing tiers (especially dyeing and finishing).

Financial Support: Co-invest with suppliers in on-site renewable projects to achieve the massive 55% total GHG reduction. Cascale

2. Invest in Regeneration (The Methane Fix)

Shift Sourcing: Prioritize and help fund the transition of supply chains toward Regenerative Agriculture for all natural fibers, ensuring they adopt both better grazing and methane-reducing feed.

Promote Circularity: Design garments for full biodegradation and promote the composting of natural fibers, turning waste into soil rather than methane. India Environment Portal

3. Decarbonize Logistics (The ∼35% Fix)

Support Electric Vehicles: Actively push suppliers and third-party logistics (3PLs) toward adopting electric vehicles and clean transport methods for both freight and last-mile delivery.

Optimize Transport: Implement measures to maximize loading efficiency and shift freight away from air travel where feasible.

4. Demand Accountability and Policy Change

Lobby for Green Grids: Advocate for energy policies that allow factories in manufacturing hubs to easily source renewable power.

Demand Fugitive Emission Regulation: Use collective brand power to demand stricter controls on methane leaks from the global oil and gas industry.

Vote for Climate Policy: Recognizing that regulation is often the most powerful tool, consumers and businesses must actively support candidates and policies that prioritize climate action, especially in regions where environmental regulations are at risk. IEA Global Methane Tracker